Sustainable Design in Technology Manufacturing

The rapid evolution of technology has brought immense convenience and innovation, yet it also presents significant environmental challenges. Sustainable design in technology manufacturing addresses these concerns by integrating eco-friendly practices throughout the product lifecycle, from material sourcing to end-of-life management. This approach aims to minimize environmental impact while still delivering high-performance digital devices.

The technology sector is at a pivotal point, recognizing the imperative to embed sustainability into its core operations. This shift involves re-evaluating traditional manufacturing processes, material selection, and product lifespans to reduce waste, conserve resources, and mitigate carbon footprints. Companies are increasingly focusing on creating durable, repairable, and recyclable products that align with circular economy principles, ensuring that the advancements in computing and connectivity do not come at an undue environmental cost.

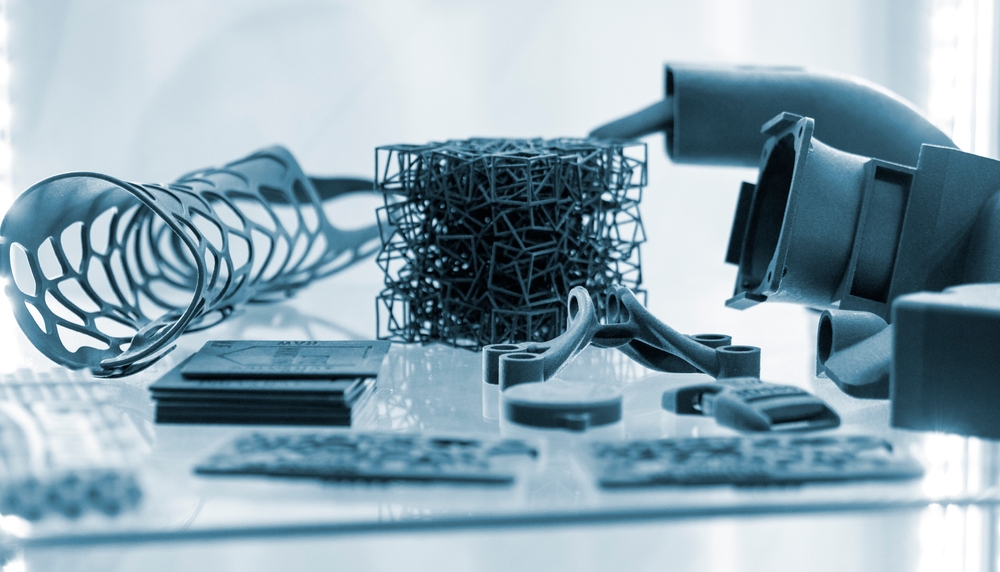

Integrating Sustainable Practices in Digital Devices

Designing digital devices with sustainability in mind begins at the conceptual stage. This involves making conscious choices about every component, from processors to displays, to ensure they are environmentally sound. Manufacturers are exploring alternatives to rare earth elements and hazardous materials, opting instead for recycled content or more abundant, less impactful substances. The goal is to develop gadgets and peripherals that not only perform exceptionally but also leave a minimal environmental footprint throughout their use and disposal. This holistic approach to product development is crucial for advancing the overall sustainability of the technology industry.

Material Choices and Circular Economy in Hardware

The selection of materials for hardware components is a critical aspect of sustainable design. Traditional electronics often rely on virgin resources, leading to significant mining and processing impacts. A move towards a circular economy model emphasizes using recycled plastics, metals, and other materials in new products. This reduces the demand for new raw materials and diverts waste from landfills. Companies are also investigating bio-based plastics and modular designs that allow for easier disassembly and recycling, extending the useful life of materials and components within the technology ecosystem. Innovations in material science are key to unlocking truly sustainable hardware.

Energy Efficiency and Computing Systems Optimization

Energy consumption is a major environmental consideration, both during manufacturing and throughout a product’s operational life. Sustainable design focuses on optimizing computing systems and networking infrastructure for maximum energy efficiency. This includes developing more efficient processors, memory, and power management units that reduce electricity usage without compromising performance. Furthermore, innovations in cooling technologies and power delivery systems contribute to lower overall energy demands for large data centers and individual devices. Addressing the energy footprint of technology is essential for reducing greenhouse gas emissions and operational costs.

Enhancing Product Longevity and Repairability

Extending the lifespan of technology products is a fundamental pillar of sustainability. This involves designing devices that are durable, upgradeable, and easy to repair. Manufacturers are moving away from proprietary components and glued-shut designs, favoring modular construction and readily available spare parts. The ability for consumers to easily repair or upgrade their gadgets, rather than replacing them, significantly reduces electronic waste. This focus on longevity not only benefits the environment but also provides greater value to consumers by allowing them to use their technology for longer periods, fostering a more sustainable consumption model.

The Role of Software and Data in Driving Sustainability

Sustainability in technology extends beyond physical hardware to include software and data management. Efficient software design can reduce the processing power and memory required by applications, thereby lowering the energy consumption of devices. Furthermore, data analytics plays a crucial role in monitoring and optimizing manufacturing processes, supply chains, and product usage patterns to identify areas for environmental improvement. From managing resource allocation to tracking product lifecycles, intelligent systems and robust data collection can provide insights that drive sustainable innovation and decision-making across the entire technology value chain, impacting everything from individual devices to complex automation systems.

Embracing sustainable design principles in technology manufacturing is an evolving journey that requires continuous innovation and collaboration across the industry. By focusing on responsible material sourcing, energy efficiency, product longevity, and the intelligent use of software and data, the technology sector can significantly reduce its environmental impact. These efforts contribute to a healthier planet while still delivering the advanced digital solutions that society relies upon.